Mazak CNC machines represent some of the most sophisticated manufacturing equipment in modern production facilities. These Japanese-engineered machines deliver exceptional precision and reliability, but like all complex machinery, they require specialized repair expertise when issues arise. Manufacturing downtime costs the average facility $50,000 per hour, making prompt and professional Mazak repair services critical for maintaining operational efficiency.

When your Mazak CNC machine experiences problems, partnering with experienced professionals becomes essential for protecting your investment. Machine tool repair and maintenance services provide the specialized knowledge needed to diagnose, repair, and restore your Mazak equipment to optimal performance levels.

Understanding Mazak CNC Machine Technology

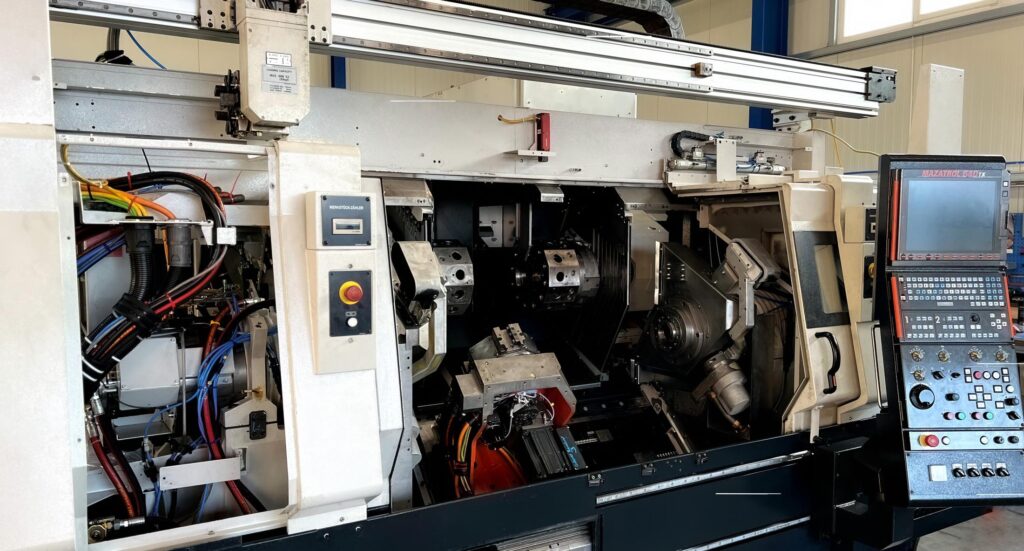

Mazak Corporation has built a reputation for producing advanced CNC machines that combine sophisticated automation with precision engineering. Their machines feature sophisticated control systems, high-speed spindles, and complex mechanical components that work together to deliver superior manufacturing results.

The complexity of Mazak machines means that repair work requires deep technical knowledge of their proprietary systems. These machines frequently incorporate advanced features like intelligent thermal compensation, adaptive control systems, and integrated automation that demand specialized diagnostic approaches.

Common Mazak CNC Machine Issues

Spindle problems represent one of the most frequent repair needs for Mazak machines. High-speed spindles endure significant stress during operation, leading to bearing wear, thermal expansion issues, and occasional catastrophic failures. Early detection of spindle problems can prevent costly secondary damage to other machine components.

Control system malfunctions can disrupt production schedules and require immediate attention. Mazak’s sophisticated control interfaces sometimes experience software glitches, memory errors, or communication breakdowns that affect machine operation. These issues frequently require both hardware and software expertise to resolve properly.

Hydraulic system failures cause significant operational disruptions in Mazak machines. These systems power tool changers, workpiece clamping, and various automated functions. Contaminated hydraulic fluid, worn seals, and pump failures can cascade into multiple system problems if not addressed quickly.

Diagnostic Approaches for Mazak Repairs

Professional Mazak repair begins with comprehensive diagnostic procedures that identify root causes rather than just symptoms. Advanced diagnostic equipment can analyze machine performance data, vibration patterns, and electrical signals to pinpoint specific problem areas.

Thermal imaging technology reveals hot spots and temperature irregularities that indicate bearing problems, electrical issues, or mechanical misalignments. This non-invasive diagnostic approach helps technicians identify problems before they cause complete machine failures.

Precision measurement tools verify machine accuracy and detect mechanical wear patterns. Laser interferometry and ball bar testing provide detailed information about machine geometry and positioning accuracy that guides repair decisions.

Specialized Repair Techniques

Mazak spindle repair requires specialized equipment and expertise due to the precision tolerances involved. Professional repair facilities use dedicated spindle analyzers, balancing equipment, and clean room environments to restore spindles to original specifications.

Control system repairs frequently involve component-level diagnostics and repairs rather than complete replacements. Experienced technicians can repair circuit boards, replace specific components, and update software to restore full functionality while minimizing costs.

Mechanical component repairs use precision machining capabilities to restore worn parts to original specifications. Many Mazak components can be repaired and restored rather than replaced, providing significant cost savings while maintaining performance standards.

Preventive Maintenance Strategies

Regular preventive maintenance extends Mazak machine life and reduces unexpected repair needs. Professional maintenance programs include scheduled inspections, fluid changes, filter replacements, and calibration checks that keep machines operating at peak efficiency.

Condition monitoring systems can track machine performance trends and identify developing problems before they cause failures. These systems monitor parameters like vibration levels, temperature patterns, and power consumption to provide early warning of potential issues.

Lubrication management plays a critical role in Mazak machine longevity. Proper lubricant selection, application schedules, and contamination control prevent premature wear and extend component life significantly.

Emergency Repair Services

Manufacturing operations cannot afford extended downtime when Mazak machines fail unexpectedly. Emergency repair services provide rapid response capabilities that minimize production disruptions and protect delivery schedules.

Mobile repair units can perform many diagnostic and repair procedures on-site, eliminating transportation delays and reducing overall downtime. These units carry specialized tools and common replacement parts to handle urgent repair needs effectively.

24/7 technical support ensures that help is available when problems occur outside normal business hours. Remote diagnostic capabilities allow technicians to begin troubleshooting immediately and guide on-site personnel through preliminary diagnostic steps.

Cost-Effective Repair Solutions

Mazak machine repairs require balancing performance restoration with budget considerations. Professional repair services can evaluate whether repairs or replacements provide better long-term value based on machine age, condition, and operational requirements.

Rebuilt component options frequently provide significant cost savings compared to new parts and deliver comparable performance and reliability. Quality rebuild programs include thorough inspections, precision machining, and comprehensive testing to guarantee reliable operation.

Warranty programs protect repair investments and provide peace of mind for critical production equipment. Comprehensive warranties cover both parts and labor and guarantee repair quality and reliability.

Optimizing Production Through Professional Repair

Professional repair services do more than fix immediate problems – they optimize machine performance to improve overall production efficiency. Effective CNC machine repair strategies focus on restoring machines to better-than-original performance levels through precision restoration and strategic upgrades.

Accuracy improvements during repair can enhance part quality and reduce scrap rates. Precision rebuilding techniques often restore machine accuracy to levels that exceed original factory specifications, providing immediate production benefits.

Performance optimization may include upgrading specific components to improve reliability, speed, or accuracy. Strategic upgrades during repair work can provide significant operational improvements while addressing immediate repair needs.

Training and Knowledge Transfer

Professional repair services often include training components that help facility maintenance teams better understand their Mazak equipment. This knowledge transfer improves daily maintenance practices and helps identify potential problems earlier.

Documentation and reporting provide valuable insights into machine condition and performance trends. Detailed repair reports help facility managers make informed decisions about maintenance schedules and capital equipment planning.

Ongoing technical support relationships ensure that facilities have access to expertise when questions arise. These partnerships provide valuable resources for troubleshooting, maintenance planning, and performance optimization.

Quality Assurance in Mazak Repairs

Professional Mazak repair services implement rigorous quality control procedures to ensure reliable results. Multiple inspection points, precision testing, and performance verification guarantee that repaired machines meet or exceed original specifications.

Calibration and accuracy testing verify that repaired machines can produce parts within required tolerances. Comprehensive testing procedures check all machine functions and safety systems before returning equipment to service.

Performance documentation provides baseline data for future maintenance and repair decisions. Detailed records help track machine performance trends and optimize maintenance schedules for individual machines.

Technology Integration and Upgrades

Modern Mazak repair services can integrate new technologies during repair processes to improve machine capabilities. Control system upgrades, automation enhancements, and connectivity improvements can provide significant operational benefits.

Retrofit options allow older Mazak machines to incorporate modern features and capabilities. Strategic retrofits during repair work can extend machine life and improve productivity without requiring complete equipment replacement.

Data collection and monitoring capabilities can be added during repair work to provide ongoing performance insights. These systems help optimize machine utilization and predict future maintenance needs.

Environmental and Safety Considerations

Professional Mazak repair services prioritize environmental responsibility and worker safety throughout all repair processes. Proper disposal of used fluids, filters, and components protects the environment while meeting regulatory requirements.

Safety system testing ensures that all protective devices function properly after repair work. Comprehensive safety checks verify that machines meet current safety standards and protect operators from potential hazards.

Energy efficiency improvements during repair can reduce operational costs and environmental impact. Upgraded components and optimized settings often improve energy consumption while maintaining or improving performance.

Future-Proofing Your Mazak Investment

Strategic repair approaches consider long-term facility needs and production requirements. Professional repair services can recommend modifications and upgrades that prepare machines for future operational demands.

Parts availability planning ensures that critical components remain available for older Mazak machines. Professional repair services maintain relationships with parts suppliers and can recommend strategic spare parts inventory.

Technology roadmap planning helps facilities understand how current repair decisions affect future upgrade options. Strategic planning ensures that repair investments align with long-term equipment strategies.

Protecting your Mazak CNC machine investment requires partnering with experienced professionals who understand these sophisticated machines. Schedule your consultation today to discuss your specific repair needs and develop a comprehensive maintenance strategy that keeps your equipment running at peak performance.

Comprehensive machine tool repair and maintenance approaches provide the foundation for reliable Mazak operation and long-term productivity success.

Industry Standards and Compliance Resources

Professional Mazak repair services must comply with various industry standards and safety regulations. The Occupational Safety and Health Administration (OSHA) provides comprehensive guidelines for machine guarding and safety requirements that apply to CNC machine operations and repair work.

The National Institute of Standards and Technology (NIST) offers valuable resources on manufacturing standards and best practices that guide professional repair procedures and quality assurance protocols.

Frequently Asked Questions

How long does a typical Mazak CNC machine repair take to complete? Repair timeframes vary significantly based on the specific problem and parts availability. Simple repairs like sensor replacements or software updates can be completed within hours, while major component rebuilds like spindle repairs may require 2-3 weeks. Emergency repairs receive priority scheduling to minimize production downtime. Professional repair services provide accurate time estimates after completing initial diagnostics and can often expedite critical repairs through dedicated resources and priority parts ordering.

What factors determine whether a Mazak machine should be repaired or replaced? Several key factors influence repair versus replacement decisions for Mazak machines. Machine age, overall condition, and availability of replacement parts play important roles in this evaluation. Repair costs compared to machine value and remaining useful life help determine economic feasibility. Production requirements, accuracy needs, and future technology plans also influence these decisions. Professional evaluation services can assess all these factors and provide objective recommendations based on your specific operational needs and budget considerations.

Can older Mazak machines be upgraded with modern control systems during repair? Many older Mazak machines can benefit from control system upgrades that improve functionality and extend useful life. Modern control retrofits can add features like advanced programming capabilities, network connectivity, and improved user interfaces. These upgrades often improve machine accuracy, reduce setup times, and enhance overall productivity. Professional evaluation determines upgrade feasibility based on machine mechanical condition and cost-benefit analysis. Strategic upgrades during major repairs can provide excellent return on investment.

What preventive maintenance schedules work best for Mazak CNC machines? Effective Mazak preventive maintenance combines manufacturer recommendations with facility-specific operating conditions. Daily checks should include fluid levels, alarm monitoring, and basic cleaning procedures. Weekly maintenance typically covers lubrication points, filter inspections, and calibration checks. Monthly maintenance includes more comprehensive inspections of mechanical components, electrical connections, and safety systems. Annual maintenance should involve precision accuracy testing, major component inspections, and software updates. Professional maintenance programs can customize schedules based on your specific machines and operating patterns.

How can I minimize downtime when my Mazak machine requires emergency repairs? Minimizing emergency repair downtime requires preparation and professional partnerships. Maintaining critical spare parts inventory helps avoid delays waiting for components. Establishing relationships with qualified repair services ensures rapid response when problems occur. Remote diagnostic capabilities allow technicians to begin troubleshooting immediately and guide preliminary repair steps. Mobile repair services can perform many procedures on-site, eliminating transportation delays. Emergency repair protocols should include clear escalation procedures and decision-making authority to avoid delays in repair authorization and parts procurement.