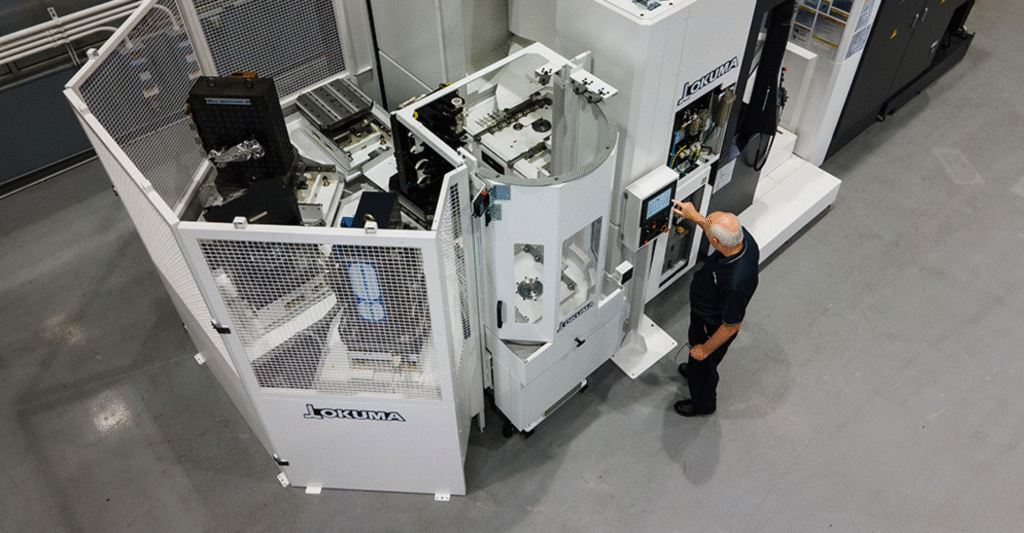

Okuma CNC Machine Repair Services for Manufacturing Excellence

When your Okuma CNC machine experiences unexpected downtime, every minute counts. Manufacturing facilities across North America depend on these precision instruments to maintain production schedules and quality standards. Machine failures can cost thousands of dollars per hour in lost productivity, making rapid, professional repair services critical for operational success. Exact Machine Service provides comprehensive Okuma …

Okuma CNC Machine Repair Services for Manufacturing Excellence Read More »