Bridgeport CNC machines have earned a reputation for durability and versatility in manufacturing environments worldwide. These American-built machines combine proven mechanical designs with modern CNC control systems, making them popular choices for general machining, toolmaking, and prototyping applications across diverse industries.

Exact Machine Service’s preventative maintenance program provides comprehensive Bridgeport CNC machine repair services that maximize equipment reliability and extend service life. Our experienced technicians understand the robust construction and control system integration that makes Bridgeport machines valuable assets in manufacturing operations.

Manufacturing facilities rely on Bridgeport equipment for its proven reliability and straightforward operation. These machines often serve as workhorses in production environments, handling diverse machining tasks with consistent performance. Professional repair services maintain the dependability and accuracy that make Bridgeport machines essential production tools.

Understanding Bridgeport CNC Machine Construction

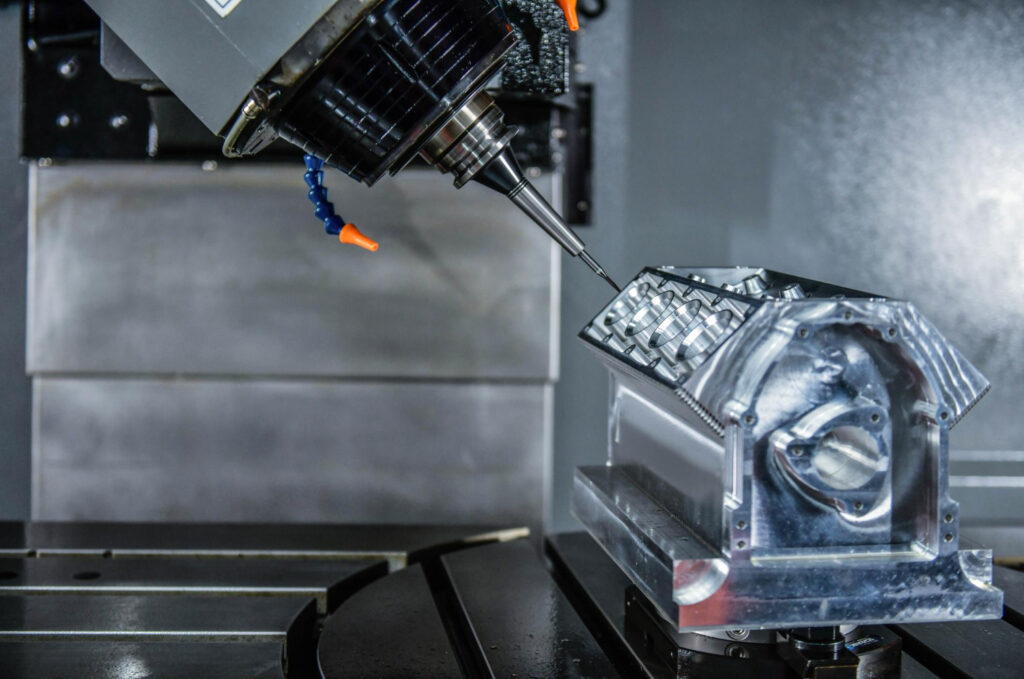

Bridgeport machines feature heavy-duty cast iron construction that provides excellent vibration damping and thermal stability. The traditional knee-type milling machine design has been successfully adapted to CNC operation while maintaining the structural integrity that defines the Bridgeport brand. Professional repair services must understand these design characteristics to maintain original performance levels.

Spindle systems in Bridgeport CNC machines utilize proven bearing configurations and lubrication systems developed through decades of manufacturing experience. These robust designs can withstand heavy cutting loads and diverse machining applications. Repair procedures must preserve the durability and reliability that operators expect from Bridgeport equipment.

Control system integration varies across different Bridgeport models, with many machines utilizing standard Fanuc or similar control systems. This standardization simplifies troubleshooting and repair procedures while providing access to readily available replacement components. Professional technicians can work efficiently with these familiar control platforms.

Common Bridgeport CNC Machine Issues and Solutions

Bridgeport machines face specific challenges related to their mechanical design and typical operating environments. Way wear represents a common problem affecting positioning accuracy and surface finish quality. These machines often operate in demanding environments that accelerate wear on critical sliding surfaces.

Spindle bearing problems can develop from contamination, inadequate lubrication, or excessive loading during heavy machining operations. Bridgeport spindles are designed for durability, yet they require proper maintenance to deliver reliable performance over extended service periods. Professional diagnosis can determine whether repair or replacement provides the most cost-effective solution.

Control system issues frequently involve aging components in older machines or programming problems related to setup changes. Standard control systems used in Bridgeport machines simplify troubleshooting procedures and component sourcing. Professional repair services can quickly identify and resolve control-related problems.

Diagnostic Procedures for Bridgeport Equipment

Comprehensive diagnostic procedures begin with mechanical inspection of critical wear points and adjustment mechanisms. Bridgeport machines incorporate numerous mechanical adjustments that affect accuracy and performance. Professional technicians understand these adjustment procedures and can identify components requiring attention.

Electrical system testing focuses on power distribution, servo amplifier performance, and control signal integrity throughout the machine. Standard electrical components used in Bridgeport machines simplify testing procedures and component identification. Systematic testing protocols can isolate problems to specific circuits or components.

Control system analysis utilizes standard diagnostic software and procedures common to most CNC equipment. Bridgeport machines typically use industry-standard controls that provide comprehensive diagnostic capabilities. Professional technicians can quickly retrieve error information and performance data to guide repair procedures.

Spindle Repair and Mechanical Rebuilding

Bridgeport spindle repair procedures focus on restoring the durability and accuracy that defines these machines. Disassembly procedures follow established protocols that protect critical components and document existing conditions. Professional repair facilities have the specialized tools and knowledge required for proper spindle service.

Bearing replacement utilizes high-quality components selected for the demanding applications typical of Bridgeport machines. Proper bearing installation requires specific preload settings and lubrication procedures that affect spindle performance and service life. Professional installation procedures restore original specifications and reliability.

Mechanical rebuilding extends beyond spindle service to include way reconditioning, ball screw replacement, and structural component repair. Bridgeport machines are built to last, and comprehensive rebuilding can restore decades of additional service life. Professional evaluation determines the most cost-effective rebuilding strategies for specific machines.

Control System Service and Upgrades

Control system service for Bridgeport machines benefits from the standardization common to these machines. Standard components simplify troubleshooting procedures and reduce repair costs compared to proprietary systems. Professional technicians can work efficiently with familiar control platforms and diagnostic procedures.

Software support includes program backup, parameter restoration, and troubleshooting assistance for operators and programmers. Bridgeport machines often run the same programs for extended periods, making program protection and backup procedures critical for production continuity.

Upgrade opportunities can modernize older Bridgeport machines with current control features and connectivity options. Retrofit programs can add programming capabilities, improve accuracy, and extend service life significantly. Professional evaluation determines upgrade feasibility and cost-effectiveness for specific applications.

Preventive Maintenance Programs for Bridgeport Reliability

Structured maintenance programs preserve the reliability that makes Bridgeport machines valuable production assets. Regular inspection schedules identify wear patterns and developing problems before they affect production quality or cause unexpected downtime. Understanding machine tool repair maintenance principles helps optimize maintenance scheduling and procedures.

Lubrication programs maintain proper fluid levels and cleanliness throughout mechanical systems. Bridgeport machines require regular attention to way lubrication, spindle greasing, and hydraulic system maintenance. Professional maintenance teams can establish schedules that optimize machine performance and component life.

Adjustment procedures maintain accuracy and performance over time. Bridgeport machines incorporate numerous mechanical adjustments that require periodic attention to compensate for normal wear. Professional maintenance includes systematic checking and adjustment of critical machine parameters.

Field Service and Emergency Repair Response

Bridgeport machines often serve critical roles in production environments that cannot tolerate extended downtime. Professional repair services provide emergency response capabilities with experienced technicians and common replacement parts. Field service capabilities minimize downtime by addressing problems at customer locations when possible.

On-site repair procedures include mechanical adjustments, electrical troubleshooting, and control system service that can be performed without removing equipment from the production floor. Many Bridgeport problems can be resolved quickly with proper diagnosis and readily available replacement components.

Remote support capabilities provide immediate assistance through phone consultation and troubleshooting guidance. Experienced technicians can guide operators through basic procedures or provide expert analysis of error conditions. This support often resolves simple problems immediately without requiring service calls.

Parts Sourcing and Component Availability

Bridgeport parts availability benefits from the popularity and standardization of these machines. Professional repair services maintain inventory levels for common components including servo motors, control modules, and mechanical assemblies. Standard components used in many machines simplify sourcing and reduce costs.

Aftermarket alternatives provide cost-effective solutions for many applications while maintaining performance standards. Generic components can often substitute for original parts at significant cost savings. Professional technicians can evaluate alternatives and determine compatibility with specific machine configurations.

Remanufactured components offer another cost-effective option for Bridgeport repairs. Professional rebuilding services can restore worn components to like-new condition at substantial savings compared to new part prices. Quality remanufacturing includes comprehensive testing and warranty coverage.

Quality Control and Performance Testing

Bridgeport repair quality control procedures verify that restored machines meet accuracy and performance standards expected from these reliable machines. Testing protocols include positioning accuracy checks, repeatability measurements, and surface finish evaluations. Professional procedures confirm that repairs restore original machine capabilities.

Documentation systems track work performed, components replaced, and test results achieved throughout repair procedures. These records provide valuable information for warranty claims, maintenance planning, and performance analysis. Professional service maintains comprehensive work histories for each machine.

Customer acceptance procedures include comprehensive demonstrations of restored machine capabilities and training on any changes or improvements made during repair. Professional service ensures that operators understand any modifications and can utilize full machine capabilities effectively.

Cost-Effective Repair Strategies for Bridgeport Equipment

Professional Bridgeport repair services provide excellent value through cost-effective solutions that extend machine life and maintain productivity. These machines are built to last, and proper repair can provide decades of additional service at a fraction of replacement cost. Detailed analysis helps customers make informed decisions about repair versus replacement.

Rebuilding programs can restore older Bridgeport machines to like-new condition while adding modern features and capabilities. Comprehensive rebuilding includes mechanical reconditioning, control system upgrades, and accuracy restoration. Professional rebuilding can provide better performance than original specifications at reasonable cost.

Phased repair approaches allow prioritization of critical systems while managing costs effectively. Emergency repairs can restore basic functionality quickly while comprehensive rebuilding is scheduled during planned downtime. This flexibility helps manufacturers maintain production schedules and budget requirements.

Technology Integration and Modernization Options

Modern connectivity features can be added to older Bridgeport machines through retrofit programs that improve data collection and production monitoring. Integration with manufacturing execution systems provides valuable production insights and scheduling information. Professional installation ensures compatibility and reliable operation.

Automation enhancements can improve productivity and reduce labor requirements for repetitive operations. Automatic tool changers, part loading systems, and measurement probes can be added to many Bridgeport machines. Professional evaluation determines feasibility and return on investment for specific applications.

CNC conversion services can modernize manual Bridgeport machines with full CNC capabilities. These conversions preserve the proven mechanical design while adding modern control and programming features. Professional conversion provides cost-effective automation for proven machine platforms.

Training and Operational Support Services

Operator training programs maximize Bridgeport machine utilization and prevent user-induced problems that could affect productivity or equipment condition. Professional training covers programming, setup procedures, and routine maintenance tasks that operators can perform safely. Well-trained operators improve efficiency and equipment reliability.

Maintenance training for shop personnel reduces service costs and improves response times for routine issues. Professional programs teach inspection techniques, lubrication procedures, and basic troubleshooting methods. Internal maintenance capability reduces dependence on outside services for routine tasks.

Programming support helps operators and programmers optimize cycle times, tool selection, and cutting parameters for specific applications. Bridgeport machines can handle diverse machining tasks, and proper programming maximizes their versatility. Professional support improves productivity and part quality. For advanced maintenance strategies, explore high-quality preventative maintenance machine life performance to understand how proper care extends Bridgeport machine service life and maintains peak performance.

Long-Term Value and Investment Protection

Bridgeport machines represent excellent long-term investments due to their proven durability and straightforward design. Professional maintenance and repair services protect these investments through expert care and quality procedures. Well-maintained Bridgeport machines can provide reliable service for decades with proper attention.

Documentation maintenance preserves service history and supports resale value when machines are eventually replaced. Complete service records demonstrate proper care and can significantly affect resale prices. Professional service providers maintain detailed documentation that supports value preservation.

Upgrade planning helps customers maximize returns from existing Bridgeport investments while preparing for future production requirements. Strategic upgrades can extend service life and improve capabilities without requiring complete equipment replacement. Professional consultation provides guidance for long-term equipment planning.

Schedule your Bridgeport CNC machine repair service today to maintain the reliability and performance that keeps your manufacturing operations productive and profitable.

Industry Standards and Compliance Resources

Professional Bridgeport repair services follow established industry standards for safety and quality throughout all service procedures. Department of Labor workplace safety standards govern technician training requirements and safety procedures during machine maintenance operations. Small Business Administration equipment financing guidelines provide resources for manufacturers seeking to finance equipment repairs or upgrades to maintain competitive operations.

Frequently Asked Questions

What are the most common problems affecting Bridgeport CNC machines? Bridgeport machines commonly experience way wear that affects positioning accuracy and surface finish quality due to their frequent use in demanding machining applications. Spindle bearing problems develop from contamination or inadequate lubrication, particularly in high-production environments. Control system issues often involve aging components in older machines or programming problems related to setup changes. Ball screw wear can cause backlash and positioning errors over time. Professional diagnostic procedures can quickly identify these problems and recommend cost-effective repair solutions that restore reliable operation.

How long do Bridgeport CNC machine repairs typically take? Repair timeframes depend on problem complexity and parts availability. Simple control system repairs or electrical troubleshooting may complete within 1-2 days. Mechanical repairs like way reconditioning or spindle rebuilding require 1-2 weeks depending on machining requirements and component availability. Complete machine rebuilds can take 3-4 weeks but provide decades of additional service life. Emergency repairs receive priority scheduling to minimize production impact. Professional repair facilities provide realistic timeframes and maintain communication throughout the process.

Can older Bridgeport machines be upgraded with modern CNC controls? Yes, many older Bridgeport machines can be successfully upgraded with current CNC control systems that provide enhanced programming capabilities and improved reliability. Retrofit programs can add features like conversational programming, tool management, and network connectivity while preserving the proven mechanical design. Cost analysis determines whether upgrades provide better value than replacement based on machine condition and production requirements. Professional evaluation considers compatibility, performance improvements, and long-term support availability for each specific situation.

What warranty coverage comes with professional Bridgeport repairs? Professional repair facilities typically provide warranty coverage ranging from 90 days to one year depending on repair complexity and components involved. Mechanical rebuilds and spindle repairs often include extended warranties reflecting the comprehensive work performed. Warranty coverage usually includes parts, labor, and accuracy guarantees when applicable. Some repair facilities offer extended warranty options for additional protection on critical production equipment. Professional facilities stand behind their work with comprehensive guarantees.

Do you provide preventive maintenance programs for Bridgeport equipment? Yes, professional repair services offer comprehensive preventive maintenance programs designed specifically for Bridgeport machines. These programs include regular inspections, lubrication services, accuracy verification, and adjustment procedures that prevent problems and extend equipment life. Customized maintenance schedules consider operating conditions, production requirements, and machine age. Preventive programs typically reduce emergency repair costs and improve overall equipment reliability. Professional maintenance includes documentation and reporting that tracks machine condition and performance trends over time.