Blog

Why CNC Machine Downtime Costs Pennsylvania Manufacturers Thousands Per Hour

Exact Machine Service: Your Partner in Precision Manufacturing Every minute a CNC machine sits idle costs money. For Pennsylvania manufacturers operating precision equipment, unplanned downtime represents one of the most significant threats to profitability, customer relationships, and competitive positioning in increasingly demanding markets. Understanding the true cost of equipment failures—and implementing strategies to minimize them—has... Continue reading→

Machine Tool Parts Sourcing: How Quality Components and Expert Support Keep Your Shop Running

Exact Machine Service: Your Partner in Precision Manufacturing Behind every productive machine shop stands a network of parts suppliers, technical resources, and service relationships that keep equipment running day after day. For Pennsylvania manufacturers operating CNC lathes, machining centers, grinding equipment, and precision manufacturing systems, the quality and availability of replacement components directly impacts production... Continue reading→

Machine Tool Industry Surges as Reshoring Transforms American Manufacturing

Exact Machine Service: Your Partner in Precision Manufacturing American manufacturing is experiencing its most significant transformation in decades. The convergence of reshoring initiatives, supply chain restructuring, and record capital investment is driving unprecedented demand for machine tools, parts, and technical expertise across Pennsylvania and the broader Mid-Atlantic region. For manufacturers navigating this landscape, understanding the... Continue reading→

Why Pennsylvania Machine Shops Are Choosing Rebuilt Equipment Over New in 2025

Small and mid-sized machine shops throughout Pennsylvania are abandoning the traditional equipment acquisition model that prioritizes new machinery regardless of cost. Instead, these manufacturers are discovering that professionally rebuilt machine tools deliver precision, reliability, and performance that rivals new equipment at 50 to 70 percent cost savings—a critical advantage when equipment financing consumes working capital... Continue reading→

High Interest Rates Drive Pennsylvania Manufacturers to Used Machine Tools as Capital Equipment Market Hits $132 Billion

Pennsylvania’s 13,058 manufacturing firms face a critical decision in 2025: invest millions in new CNC machines or find cost-effective alternatives that preserve cash flow while maintaining competitive capabilities. With the global machine tools market reaching $132.6 billion and interest rates on equipment loans hovering between 5 and 8 percent, manufacturers across the Commonwealth are discovering... Continue reading→

CNC Machine Tool Depreciation: When Used Equipment Outperforms New Machinery

Pennsylvania manufacturers operating in competitive markets face a brutal financial reality: new CNC machine tools lose 30 to 40 percent of their value within five years while delivering identical production capability throughout their service lives. This CNC machine tool depreciation pattern creates extraordinary opportunities for informed buyers who understand that equipment capability and equipment value... Continue reading→

The Hidden Costs of Skipping Regular CNC Machine Maintenance: What Mid-Atlantic Manufacturers Need to Know

Mid-Atlantic manufacturing facilities operate under constant pressure to maximize production uptime and minimize operational expenses, creating powerful incentives to defer maintenance activities that interrupt output. This short-term thinking generates catastrophic long-term consequences as postponed calibration checks, skipped lubrication schedules, and ignored early warning signs compound into equipment failures that halt production for days rather than... Continue reading→

Laser Alignment vs. Manual Calibration: Accuracy Standards for Modern CNC Operations

Pennsylvania manufacturers investing hundreds of thousands of dollars in precision CNC equipment face a fundamental question that directly impacts production quality and long-term operational costs: should calibration rely on traditional manual techniques or advanced laser-based measurement systems? This decision extends beyond simple preference or budget considerations to encompass accuracy requirements, production tolerances, regulatory compliance obligations,... Continue reading→

How CNC Machine Calibration Prevents Costly Production Downtime in Pennsylvania Manufacturing

Manufacturing facilities across Pennsylvania face an invisible threat that drains profitability more effectively than any competitor: unplanned production downtime. Recent industry research reveals that Fortune Global 500 manufacturers collectively lose $1.4 trillion annually to unexpected equipment failures, with automotive plants experiencing costs exceeding $2.3 million per hour when production lines halt unexpectedly. For Pennsylvania’s diverse... Continue reading→

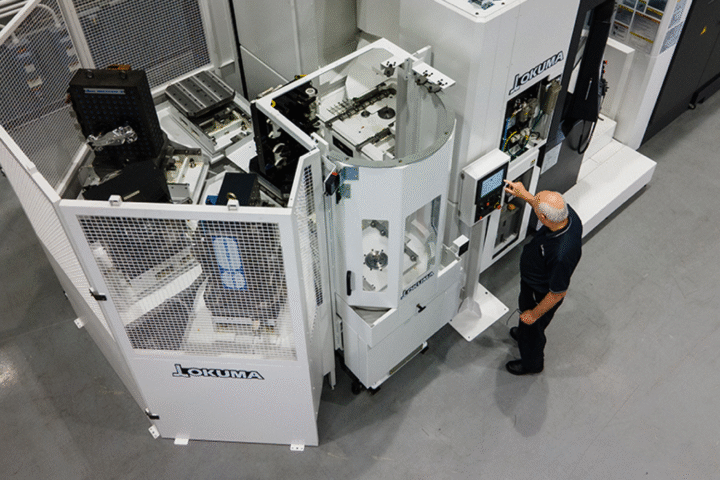

Okuma CNC Machine Repair Services for Manufacturing Excellence

When your Okuma CNC machine experiences unexpected downtime, every minute counts. Manufacturing facilities across North America depend on these precision instruments to maintain production schedules and quality standards. Machine failures can cost thousands of dollars per hour in lost productivity, making rapid, professional repair services critical for operational success. Exact Machine Service provides comprehensive Okuma... Continue reading→